Most pharmacies spend 80% of their drug budget on just 20% of their inventory. The trick? That 20% is mostly generic drugs. If you’re stocking generics the same way you stocked brand-name meds ten years ago, you’re losing money - and patients.

Why Generic Stocking Isn’t Just About Saving Money

Generic drugs make up 90% of all prescriptions filled in the U.S., but they only account for 20% of total drug spending. That’s not a typo. A bottle of generic metformin costs $4. A brand-name version? $300. Yet, many pharmacies still treat generics like low-priority items - ordering them in bulk, forgetting about expiry dates, or worse, not tracking them at all. Here’s the reality: generics aren’t cheap because they’re low quality. They’re cheap because they’re mass-produced after patents expire. That means you can afford to keep more on hand - but only if you manage them right. Stocking too little? You get stockouts. Stocking too much? You get expired pills gathering dust in the back room.The 80/20 Rule in Action: Focus on What Moves

Not all generics are created equal. Some move fast. Others sit for months. The key is identifying which ones are your top performers. Fast-moving generics include:- Metformin (type 2 diabetes)

- Atorvastatin (cholesterol)

- Lisinopril (blood pressure)

- Levothyroxine (thyroid)

- Omeprazole (acid reflux)

- Albuterol inhalers (asthma)

How to Calculate When to Reorder (ROP and ROQ)

You don’t guess when to reorder. You calculate it. Reorder Point (ROP) tells you when to place an order. Use this formula:ROP = (Average Daily Usage × Lead Time in Days) + Safety Stock

Let’s say you sell 4 bottles of lisinopril per day. Your wholesaler takes 5 days to deliver. Your safety stock is 2 bottles.ROP = (4 × 5) + 2 = 22 bottles

When your stock hits 22 bottles, trigger the order. Don’t wait until you’re down to 5. By then, you’re already risking a stockout. Reorder Quantity (ROQ) tells you how much to order. For generics, the Economic Order Quantity (EOQ) model works best. It balances ordering costs against storage costs. Most pharmacy software does this automatically - but only if you’ve set it up correctly.The Minimum/Maximum Method: Your Simplest Weapon

If your system doesn’t do EOQ, use the minimum/maximum method. It’s old-school, but it works. Set two numbers for each generic:- Minimum: The lowest stock level before you reorder. This is your ROP.

- Maximum: The most you want to keep on hand. This prevents overstocking.

What Happens When a New Generic Hits the Market?

This is where most pharmacies break. Let’s say a new generic version of atorvastatin gets approved. The brand-name version drops from $120 to $18 per bottle. Patients switch. Prescribers switch. Your inventory? Still full of the old brand. You now have $3,200 worth of pills that no one wants. The fix? As soon as a new generic is approved, you adjust your inventory system. Reduce the max for the brand-name version. Increase the max for the generic. Do it before the first prescription is filled. Don’t wait for sales data - it’s already too late. Pharmacies that do this well see a 12-18% boost in inventory turnover. That means your money isn’t sitting on shelves - it’s back in your bank account.Expiry Dates Are Your Silent Killer

Generics often have shorter shelf lives because manufacturers cut corners to keep prices low. A bottle of generic insulin might expire in 18 months instead of 24. A generic antibiotic? Maybe 12. Your software must flag items with less than 90 days until expiry. Don’t wait for the pharmacy tech to notice. Automate it. When an item hits 60 days out, offer it as a discount to patients who need it. Or return it to your wholesaler if they accept expired stock. Most do - if you document it properly. One pharmacy in Ohio lost $8,000 last year because they didn’t track expiry dates on generic thyroid meds. They were buying in bulk to save money. The savings vanished in waste.Training Staff: The Missing Piece

You can have the best software in the world, but if your staff doesn’t know how to use it, you’re wasting time. Train them on:- How to enter new generic SKUs correctly (don’t just copy-paste the brand name)

- How to return unclaimed prescriptions within 24 hours (this cuts inventory errors by 22%)

- How to flag slow-moving items for review

- Monitor FDA announcements for new generic approvals.

- Update inventory max/min within 24 hours of approval.

- Notify prescribers about the switch (use therapeutic interchange protocols if allowed in your state).

- Run a report weekly to check if brand-name stock is dropping as expected.

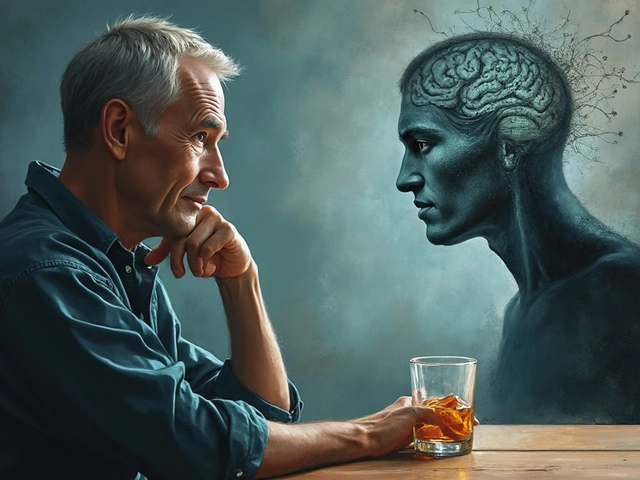

What Happens When You Don’t Do This?

You get:- Stockouts on metformin - patients go to CVS instead.

- Expired lisinopril in the back - $2,000 down the drain.

- Overstocked gabapentin that’s been sitting since 2022 - tying up cash you need for rent.

- Prescribers frustrated because you don’t have the generic they asked for.

Technology That Actually Helps

You don’t need AI. But you do need software that can:- Track ROP and ROQ for each generic

- Flag items nearing expiry

- Adjust inventory levels automatically when a new generic enters the market

- Generate weekly reports on turnover rates

Real Results From Real Pharmacies

Mark Johnson, owner of a small pharmacy in New Mexico, switched to automated refill sync for maintenance generics. His inventory costs dropped 18%. His fill rate went up 12%. He didn’t hire anyone. He just fixed his system. Lisa Chen, a manager in California, lost $3,200 when she didn’t adjust her inventory fast enough during the atorvastatin transition. She now checks FDA updates every Monday morning. David Rodriguez in Arizona used therapeutic interchange protocols to let pharmacists switch patients to generics without waiting for a new prescription. He cut patient medication gaps by 47% in one quarter. These aren’t outliers. They’re the result of simple, consistent actions.Start Small. Fix One Thing.

You don’t need to overhaul everything tomorrow. Pick one fast-moving generic - say, metformin. Do this:- Check your current stock level.

- Calculate your daily usage over the last 30 days.

- Set your ROP: (daily use × 5-day lead time) + 20% safety stock.

- Set your max at 2 weeks’ supply.

- Enable expiry alerts for this item.

- Check your stock every Friday for the next month.

Final Thought: Generics Are Your Advantage

You’re not just a pharmacy. You’re a cost-saving partner for your patients. Generics let you do that - if you manage them well. The market is changing. New generics hit the shelves every week. Patients expect you to have them. Prescribers count on you to make the switch. Don’t let your inventory system hold you back. Fix it. One generic at a time.How do I know which generics to stock more of?

Track your sales data over the last 90 days. Look for generics with high volume and low cost - like metformin, lisinopril, or omeprazole. These are your top performers. Use your pharmacy software to sort by turnover rate. Items that sell more than 20 units per week and cost less than $10 per unit are prime candidates for higher stock levels.

What’s the best way to avoid expired generics?

Set expiry alerts in your software for items with less than 90 days left. When an item hits 60 days, offer it as a discount to patients who need it. Return expired stock to your wholesaler if they allow it. Never assume generics last as long as brand-name drugs - many have 12-18 month shelf lives due to lower manufacturing standards.

Should I stock multiple brands of the same generic?

Yes - but only for fast-moving items. For example, keep 3-4 different suppliers of metformin. Patients feel more confident when they see options. Plus, if one supplier has a delay, you still have stock. Don’t do this for slow-movers - it just ties up cash.

How often should I review my generic inventory?

Weekly during transitions (like when a new generic launches), and monthly otherwise. Run a report that shows your top 10 generics by turnover and bottom 10 by movement. Cut the slow ones. Increase the fast ones. Adjust your reorder points every quarter based on seasonal trends - like more albuterol in winter.

Can I use AI for generic inventory management?

Yes - but don’t rely on it blindly. AI can predict demand and auto-reorder, but it doesn’t know if a patient has kidney issues or can’t afford a new generic. Use AI to flag trends, but always let a pharmacist make the final call. Systems that combine AI with human oversight reduce stockouts by 28% and waste by 35%.

What’s the biggest mistake pharmacies make with generics?

Waiting for sales data to change before adjusting inventory. If a new generic hits the market, don’t wait for brand-name sales to drop. Change your max/min levels immediately. The delay is what causes $2,000-$5,000 in obsolete stock. Speed matters more than accuracy here.

Arun ana

December 15, 2025 AT 17:20Man, this is so true 😅 I run a small pharmacy in Bangalore and we switched to the min/max system last year. Metformin stockouts dropped by 90%. Now we just check the alerts every morning with our chai. No fancy AI needed, just discipline and a good spreadsheet.

Dave Alponvyr

December 15, 2025 AT 18:15So you're telling me pharmacists are still manually counting pills like it's 2003? 🤦♂️

Cassandra Collins

December 16, 2025 AT 15:46EVERYTHING YOU SAID IS A LIE. THE GOVERNMENT AND BIG PHARMA ARE HIDING THE TRUTH ABOUT GENERICS. THEY'RE FULL OF TOXINS AND MICROCHIPS TO TRACK US. I SAW IT ON A FORUM. MY COUSIN'S FRIEND WORKED AT A LAB AND THEY ALL GOT PAID TO SILENCE THIS. WHY DO YOU THINK THEY PUSH GENERICS SO HARD? THEY WANT TO CONTROL OUR BODIES. ALSO MY DOG GOT SICK AFTER I GAVE HIM MY LISINOPRIL AND NOW HE BARKS IN CODE. 🚨💊

Tiffany Machelski

December 18, 2025 AT 11:45thanks for this i just started working at a pharmacy and i had no idea about rop and roq. i thought we just ordered when we ran out. i just set up my first min/max for atorvastatin and it feels so good to not panic every time someone asks for it. ty ty

Dan Padgett

December 19, 2025 AT 11:57You know, in my village back in Nigeria, we used to trade herbs and roots like currency. No barcode, no software - just memory, trust, and a keen eye. But here? We’ve got machines that can calculate your stock before you even blink. And yet, we still forget to check expiry dates. Funny how progress doesn’t always mean wisdom. Maybe the real innovation isn’t in the algorithm - it’s in remembering that someone’s life depends on that pill being right.

Hadi Santoso

December 21, 2025 AT 00:25Love this. I’m from Indonesia and we’ve got a similar system here - but we call it ‘jaga stok, jaga nyawa’ - keep stock, keep life. We even have a weekly huddle where the techs shout out which generics are about to expire. It’s chaotic but it works. Also, we stock three brands of metformin because patients get weird about the color of the pill. One guy refused to take it unless it was blue. I swear to god.

Kayleigh Campbell

December 21, 2025 AT 23:17Someone spent 2000 words explaining how to not run out of metformin. Meanwhile, I’m over here trying to convince my 80-year-old patient that her $3 generic isn’t ‘fake’ because it doesn’t have the same logo as the brand. 🤦♀️

Elizabeth Bauman

December 22, 2025 AT 22:57THIS IS WHY AMERICA IS LOSING. WE USED TO MAKE OUR OWN DRUGS. NOW WE LET CHINA MAKE OUR METFORMIN AND THEN WE TELL PHARMACISTS TO ‘MANAGE INVENTORY.’ WHAT HAPPENED TO AMERICAN INNOVATION? I’M SICK OF THIS. WE NEED TO BRING BACK DOMESTIC GENERIC PRODUCTION. NO MORE IMPORTS. NO MORE EXPIRED PILLS. NO MORE ‘RELEX’ OR ‘CLOTOUCH’ - JUST AMERICAN WORK ETHIC.

Dylan Smith

December 24, 2025 AT 06:18Just did the metformin test. Daily use 15. Lead time 5. Safety stock 3. ROP = 78. Max = 140. Set it. Checked Friday. Still at 82. No stockout. No waste. Just… quiet victory. I didn’t even need to say anything to anyone. It just worked.